1954 Singer 99K

Late last year I had the opportunity to bring a Singer 99K from 1954 back to working order. From what I can remember, it hadn’t been used since the 70’s or 80’s. I have a deep seeded love for antique things, much of the photography I do is with cameras nearly 100 years old. Needless to say, I jumped at the chance to bring another old piece of equipment back to life.

For it’s age, this machine was in really good shape. Naturally it had some rust, needed oiling, and a couple new parts that had deteriorated over the years. The photo above is after I brought it in, took the electronics off and gave it a half descent dusting. The big worry I had for the project was frayed wires on the power cord that plugs into the wall. I like to think that I’m competent enough with wiring to get away with a lot of things, but I had two issues with this in particular. The first being that I couldn’t just order new parts and swap them out, nobody makes 1950’s wiring any more. On the subject of nobody making 1950’s wiring anymore, the second problem was that I really didn’t have a chance to mess it up. With not being able to get more parts and keep it close to original, I couldn’t just fry the electronics and order another piece if I made a mistake. So I saved that for last.

Now for something I know how to do. Mechanics! I pulled the front plate of the machine, and was actually delighted to see that nothing was out of place, most sewing machines have nearly the exact same way of operating, all the way up to the big longarm quilting machines. Seeing this, I quickly got to work on taking the top end apart and polished everything that would let me. After a good cleaning and generous amounts of oil, the front was back together in no time.

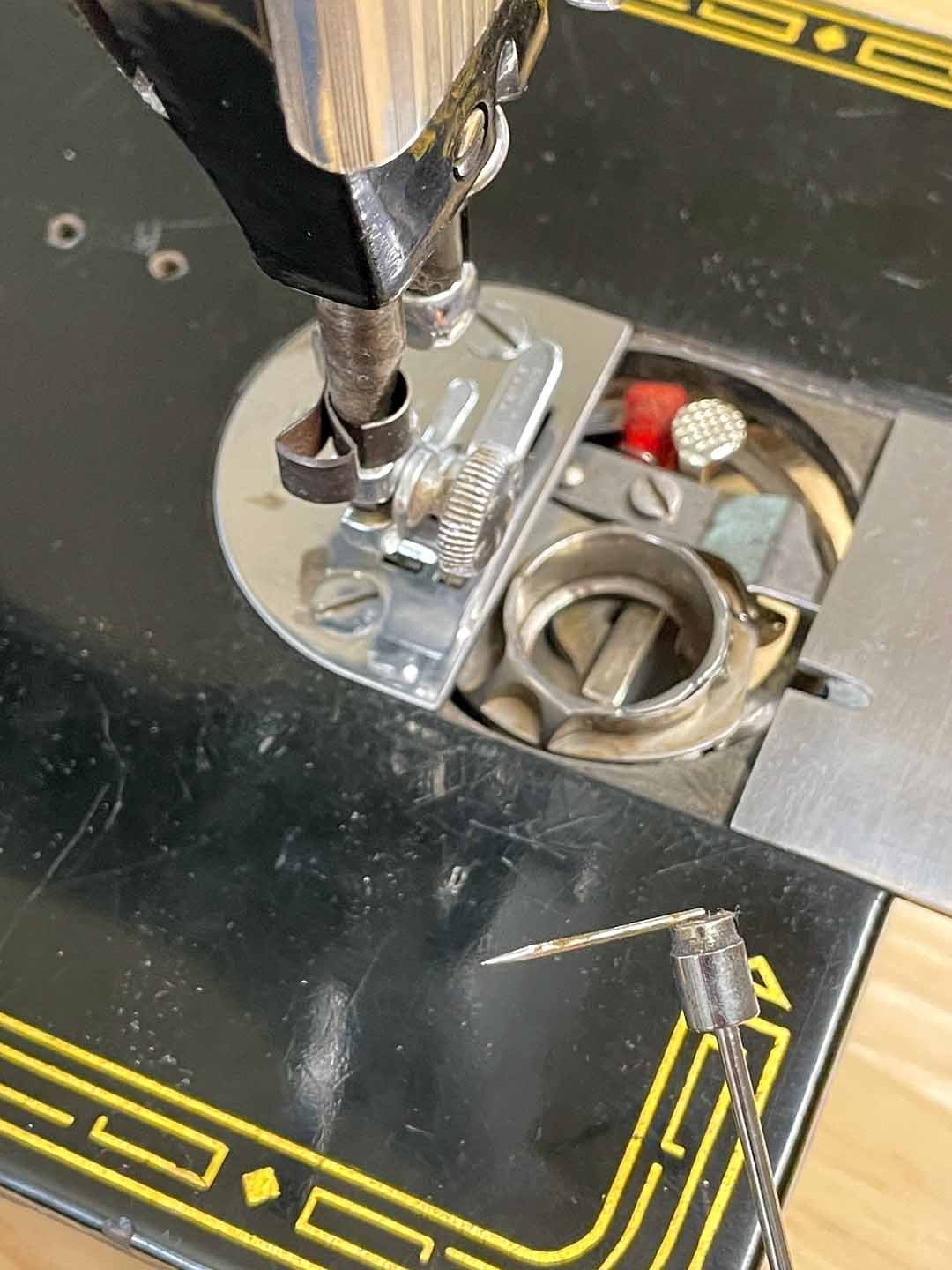

After the front was put back together, it was time to move to the bobbin area and hook assembly. Opening it up, all seemed in order. As with the top, it seemed to be put together the same way any other sewing machine is. So I set to cleaning. Pretty early on I noticed that the machine was getting stuck in a certain spot, and it hadn’t been before. After some careful digging around, I found the source of the problem. Just a broken needle. I naively was relieved that this was going to be my big headache for the job, not remembering that I still had to fix the wires for the motor.

Starting on the back of the machine, I had one straight forward job that brought me closer to my impending doom. The drive belt was completely rotted, and I had to order a new one (which I was amazed that I could). This reminded me of what the drive belt attaches to. The motor, the electric motor. So I ordered the belt and put off the wiring, getting busy cleaning and oiling the hand wheel assembly and the lower parts of the machine. These were very straight forward and were so easily accessible that I didn’t have to disassemble much.

The belt arrived a few days later, quickly followed by my sense of dread.

I’ll let you in on my anxiety, even though it might not be rational. There are a couple things that worry me about 1950’s electronics. The one that makes sense is that I can’t get replacement parts if I mess up, this has to be done correctly the first time. Now I’ve done jobs like this before, so it shouldn’t be too big of a deal, right? The second thing that made my blood pressure rise was the idea of 1950’s electronics. In my mind, the 1950’s was survival of the fittest if you decided to shake hands with electric current. I really didn’t feel like getting 1950’s zapped, starting a fire, or frying irreplaceable 70 year old electronics.

I know I could have just wrapped some electrical tape around the frayed wires and called it a day, but I stubbornly refuse to do work like that. I needed to use heat shrink to do it right, which meant I had to disconnect the power cable. Once I disconnected it, I realized that I didn’t label one of the wires. My lack of forethought taunted me, and I settled on a new way of thinking. There were only two wires to deal with, so I had a 50% chance of getting it right. But I also had a 50% chance of getting 1950’s zapped, starting a fire, or frying irreplaceable 70 year old electronics.

With some difficulty, I managed to get the wires reattached after heat shrinking the damaged areas. Then with some more difficulty, mounted the motor to the machine. The moment of truth had come, I plugged it in. Nothing happened, no zapping or fires. When I started the motor, not much happened either, it wouldn’t bring the needle up. Did you know that the hand wheel can’t be too tight, or else it will not allow the machine to turn freely? Me neither. After figuring that out, it ran like a… well like an old sewing machine.

This Singer really was a joy to work on, and an excellent example of the breed. For being more than 70 years old, and having not been used for 20 or 30 years it was in remarkable shape. The owner of this machine still has the original manual and many of the accessories that came with it in 1954. I hope I get the opportunity to work with more of these machines soon.

-Patrick